Introduction: A Persistent Challenge in Seal Reliability

The nuclear industry requires a significant amount of processing and pumping of water throughout their operations for the safety and reliability of the overall power plant. At this particular plant the maintenance of the screen wash pumps in the intake pumping station proved to be a reliability headache. For years, these pumps faced chronic issues with seal reliability. A combination of mechanical seals and packing frequently leaked, leading to maintenance headaches and challenging work conditions. The operators needed a better solution—one that was reliable, easier to install, and built to last.

The answer came in the form of Flexaseal’s Style 85 Split Cartridge Mechanical Seal, and it proved to be a game-changer.

The Problem: Leaking Seals and Difficult Maintenance

This plant uses screen wash pumps to ensure debris-free operation of its condenser circulating water pumps. These pumps rely on high-pressure water to keep traveling screens clean. However, the existing sealing solutions—a combination of packing and a competitor’s four-piece split mechanical seals—posed significant problems:

- Frequent Leakage: The seals were prone to leakage, creating housekeeping challenges in the basement of the intake pumping station.

- Complicated Installation: Installing the four-piece split seal required handling delicate subcomponents and using adapter plates to fit the seal gland. The process was cumbersome and prone to errors.

- Short Seal Life: Even with careful maintenance, the seals needed replacement more frequently than desired, and there was a 50/50 chance of excessive leakage upon startup.

The reliability of the sealing system was falling short of the plant’s operational and maintenance goals. It was time for a more effective solution.

The Solution: Flexaseal Style 85

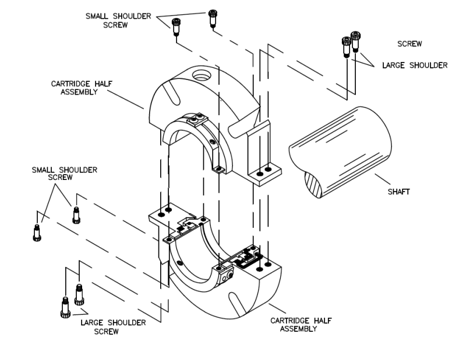

The operators turned to Flexaseal’s Style 85 Split Cartridge Mechanical Seal, a pioneering design with engineered features that address the precise challenges faced by the plant. What sets this seal apart?

- Simplified Design: Unlike traditional split seals, the Style 85 consists of only two pieces, eliminating the need to handle internal components like O-rings and springs. Dowel pins precisely align the halves, ensuring accurate installation every time.

- Ease of Installation: The split design allows the seal to be installed without disassembling the pump. This reduces equipment downtime and simplifies maintenance.

- Customization for the installation:

- A custom shaft sleeve and drive collar were designed to accommodate the unique specifications of the Worthington 6LR-16 horizontal split case pumps.

- Modifications included increasing the gland outer diameter to fully engage with the gland studs, ensuring a secure fit.

These features made the Style 85 an ideal choice for the demanding environment of this operation.

Implementation and Results: A Seamless Transition

The first installation of the Flexaseal Style 85 occurred in March 2023 on one of the plant’s Screen Wash Pumps. As of this writing, February 2025, it is still running leak-free. The installation team was impressed:

- The install process took just one hour, a stark contrast to the time-intensive installations of the previous seals.

- The custom modifications, including the stepped sleeve design, worked flawlessly.

- Operators noted this installation as the easiest split mechanical seal they had installed to date.

Following this success, the Style 85 seal was approved for all four screen wash pumps, with plans to replace the remaining four-piece split seals as they fail. The plant also committed to stocking two Style 85 seals as spares while phasing out the prior competitor seals entirely.

The Impact: Improved Efficiency and Reliability

The adoption of the Flexaseal Style 85 has delivered tangible benefits:

- Reduced Maintenance Downtime: The straightforward installation and robust design of the Style 85 minimize the time and effort required for maintenance.

- Enhanced Seal Performance: The seal’s hydraulically balanced design ensures long-lasting reliability, reducing the frequency of replacements.

- Improved Workplace Conditions: By virtually eliminating leakage, the seals have significantly improved housekeeping in the pump station.

Conclusion: Sealing Success at Speed

For nuclear power plant, the transition to Flexaseal’s Style 85 Split Cartridge Mechanical Seal represents more than just a change in equipment. It’s a testament to the power of innovative engineering and customized solutions in addressing real-world challenges. The plant now operates with greater efficiency, reliability, and confidence in its screen wash pumps—thanks to Flexaseal’s dedication to delivering solutions at the speed of need.

Learn More

Interested in how Flexaseal can solve your mechanical sealing challenges? Explore our solutions today and discover the power of seals that work as hard as you do.