Nearly 50% of equipment breakdowns are attributed to poorly aligned shafts.

When your motors and pumps are properly aligned, both units perform at optimal levels. However, misalignment puts strain on both the motors and the pumps, leading to damaged components, higher energy costs and increased downtime.

Motor Shaft Misalignment

Misalignment is not a problem that will jump out at you. Just as with your truck or car, you can get where you’re going with your alignment out of whack. But also like your vehicle, misalignment is costly in reduced performance and higher expenses down the road as your equipment is degraded.

Motor Shaft Misalignment

Causes of Misaligment

- Relative Movement

- Strain

- Torsional Movement

- Settling

- Misbored Couplings

- Human Error

Effects of Misaligment

- Excessive Vibration

- Noise

- Lost Production

- Poor Quality of Products

- Higher Than Normal Repair Orders

- Increased Inventory of Spare Parts

- Reduced Profits

Misalignment has a direct impact on power consumption.

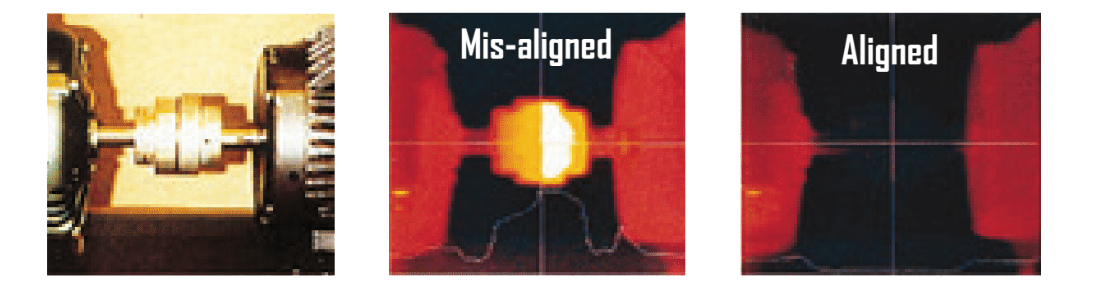

Documented cases have shown savings ranging from 2 to 17%. The thermogram below shows the coupling and the amount of heat generated due to misalignment.

Motor And Machine Alignment Services

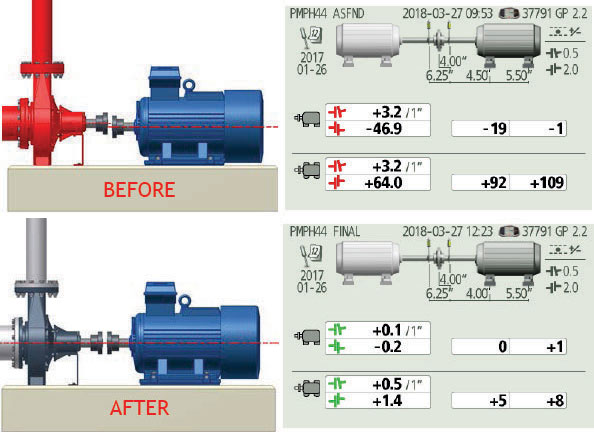

Flexaseal’s Technical Products, Inc. has the expertise to get your equipment back into alignment and running optimally. We utilize a laser-based diagnostic tool for vertical and horizontal alignments that is far more precise than traditional dial indicators or straitedges.

Our laser alignment service includes the following:

- Complete inspection including the base, feet, shims, bolts and couplings

- Laser-based measurement of alignment and vibration level

- Corrective laser alignment adjustments on the motor drive-pump with tighter tolerances than coupling and bearing manufacturers’ specifications

- Detailed report including tips on preventative measures for maintaining performance