API Piping Plans

Seal support plans and their associated systems are critical to the longevity and reliability of mechanical seals in rotating equipment. The API Seal Plans shown here are in conformance with API 682 4th edition / API 610 10th edition.

These standardized flush and support systems are widely used throughout industry. Custom variants are also possible to meet specific application conditions and requirements, so called API Plan 99 systems.

Contact Flexaseal for any of your seal support systems needs or questions at sales@flexaseal.com or by calling +1 (832) 804-7424.

Filter by Application

Filter by Plans

Filter by Application

Filter by Plans

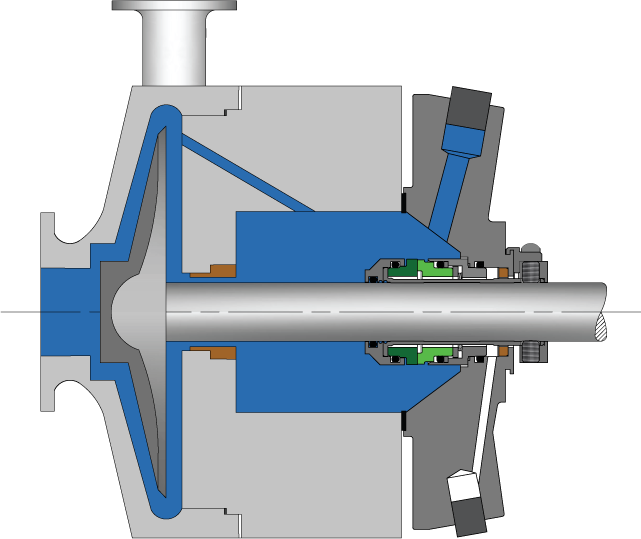

API Plan 02

Dead-ended seal chamber with no recirculation of fluid and optional cooling/heating jacket.

API Plan 11

Recirculation from pump discharge through a flow control orifice to the seal chamber.

API Plan 12

Recirculation from pump discharge through a strainer and flow control orifice to the seal chamber.

API Plan 13

Recirculation from the seal chamber through a flow control orifice to pump suction.

API Plan 14

Recirculation from pump discharge through a flow control orifice to the seal chamber and from the seal chamber through a flow control orifice to pump suction.

API Plan 21

Recirculation from pump discharge through a flow control orifice and cooler to the seal chamber.

API Plan 22

Recirculation from pump discharge through a strainer, flow control orifice, and cooler to the seal chamber.

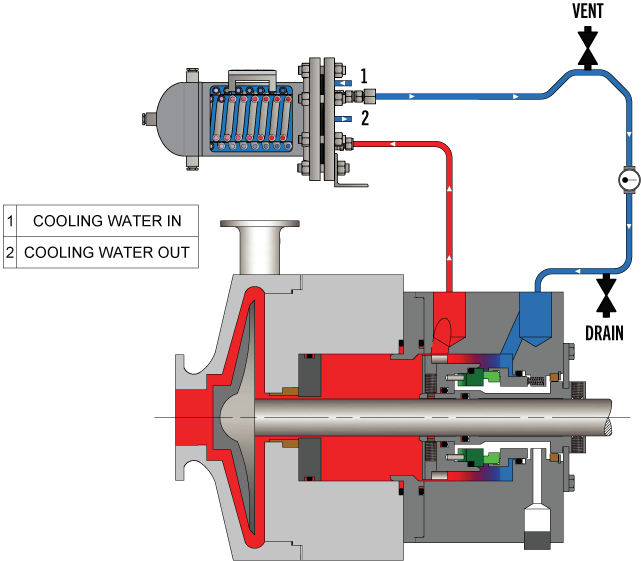

API Plan 23

Forced circulation from the seal chamber through a cooler and back to the seal chamber.

API Plan 31

Recirculation from pump discharge through a cyclone separator, delivering clean fluid to the seal chamber and solids to pump suction.

API Plan 41

Recirculation from pump discharge through a cyclone separator delivering clean fluid to a cooler and then to the seal chamber. Solids are delivered to pump suction.

API Plan 51

External reservoir providing a dead-ended fluid blanket to the quench connection.

API Plan 52

External buffer liquid reservoir supplying clean fluid to the outboard seal faces.

API Plan 53A

Pressurized external barrier liquid reservoir supplying clean fluid to the inboard and outboard seal faces.

API Plan 53B

External barrier liquid system pressurized by a bladder accumulator supplying clean fluid to the inboard and outboard seal faces.

API Plan 53C

External barrier liquid system pressurized by a piston accumulator supplying clean fluid to the inboard and outboard seal faces.

API Plan 54

Pressurized external barrier liquid system supplying clean fluid to the inboard and outboard seal faces.

API Plan 55

Unpressurized external buffer liquid system supplying clean fluid to the inboard and outboard seal faces.

API Plan 62

Quench stream is brought from an external source to the atmospheric side of the seal.

API Plan 65A

Atmospheric leakage collection and detection system for condensing leakage. Seal failure is detected by an excessive flow rate into the leakage collection system.

API Plan 65B

Atmospheric leakage collection and detection system for condensing leakage. Seal failure is detected by cumulative leakage into the leakage collection system.

API Plan 66A

Throttle bushings in the seal gland minimize the leakage leaving the seal gland and allows for detection of a seal failure.

API Plan 66B

An orifice plug in the drain port minimizes the seal leakage leaving the seal gland and allows for detection of a seal failure.

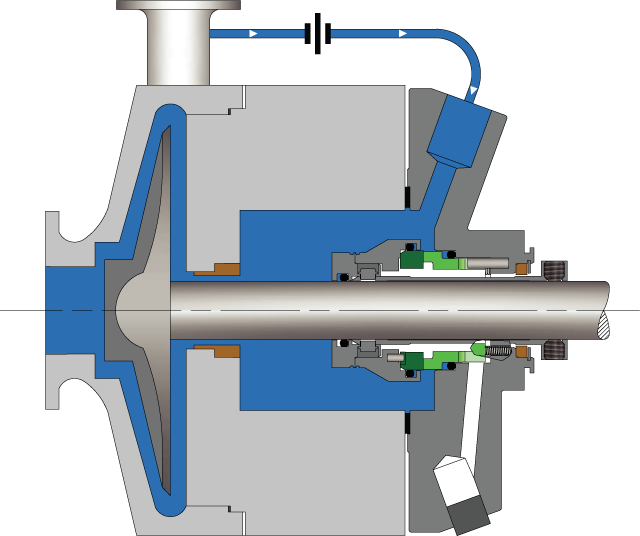

API Plan 71

Tapped connections for the purchaser’s use in the future for buffer gas applications.

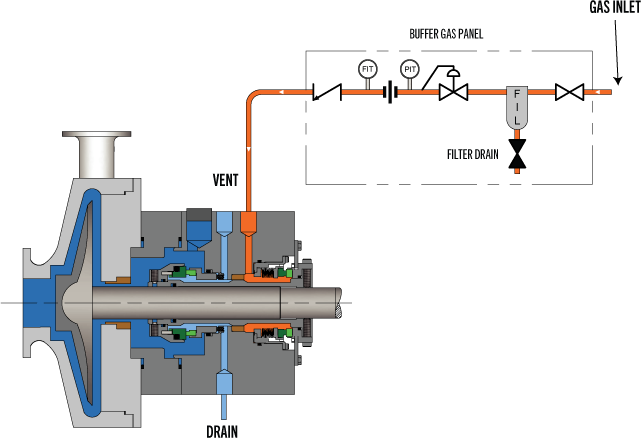

API Plan 72

Externally supplied buffer gas maintained at a pressure less than the seal chamber pressure.

API Plan 74

Externally supplied barrier gas maintained at a pressure greater than the seal chamber pressure.

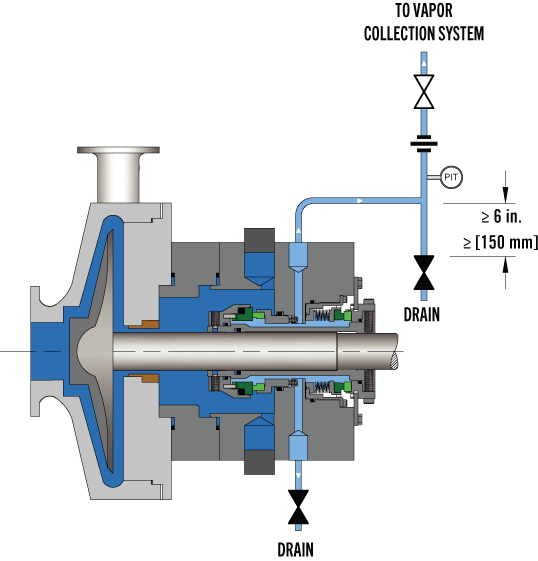

API Plan 75

Leakage collection system for condensing or mixed phase leakage with a contacting containment seal.