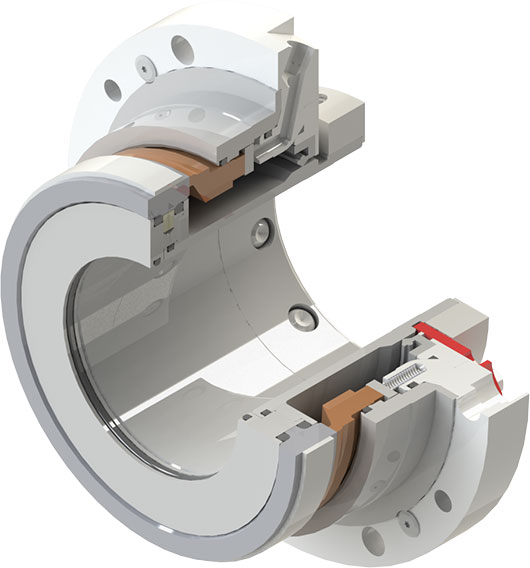

Mechanical Seal Style RKCS

Heavy Duty Flushless Slurry Pump Seal

Reliability and savings for the Slurry Pump Seal Market

The Rock Killer Crusher (RKC) Series seals are built for the harshest applications in slurry pumping, which can be found in mining, mineral processing, flue gas desulfurization and many others.

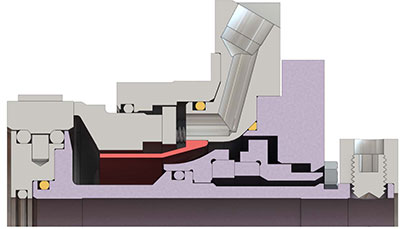

The RKCS Series is a single cartridge slurry seal designed with ease of maintenance in mind, and it is meant to be operated with zero external flushing.

With four (4) configuration options all incorporating additional engineered features such as reverse pressure capability, non-clogging multi-springs, rugged seal drive operation, and hydraulically balanced faces, the RKCS single and RKCD dual seals successfully contend with the industry’s toughest slurry challenges.

Mechanical Seal Style RKCS

Design Features & Benefits

Why the RKCS?

- Ease of fitment, simple maintenance cartridge design with popular slurry pump conversion kits available

- Abrasion and corrosion resistant materials promote longevity in service

- Seal design together with pump features coordinate to allow single-face flushless sealing of slurries up to 60%solids by weight

- Stationary face mutlispring design has springs isolated and far from pumped media

- Large and open inner seal chamber that self-evacuates and doesn’t pack in and hold heat

- For special circumstances, outboard lip seal installed and Plan 62 grease or water quench provide lubrication to the seal faces during dry-running pump cycles

Specifications

Materials of Construction

| Inboard Faces: | Ni-B Tungsten Carbide, Sintered Silicon Carbide, Graphite Loaded Silicon |

| Outboard Faces: | Antimony Impregnated Carbon, Silicon Carbide |

| Elastomers: | FKM standard Other materials available by request |

| Springs: | Alloy C276 |

| Metallurgy: | 316 SS with Alloy 255 or High Chromium Iron wetted |

Note: Other materials available by request.

Operating Parameters

| Shaft Sizes: | Up to 20.0” (508 mm) |

| Product Pressure: | 500 psi (34.5 bar) |

| Temperature: | -4° to 425°F (-20° to 218°C) |

| Speed: | Up to 3600 fpm (18.3 m/s) |

| Viscosity: | Up to 2500 cP (2.5 Pa*s) |

Note: Maximum viscosity/temperature/speed/pressure indicates operating extremes independently and does not imply the seal will function at these extremes at the same time.

Downloads

For more information on the RKCS

Quote Request

Depending on your specific needs and application, Flexaseal can help you identify the ideal products. Contact us to tell us about your needs and request a quote.

The RKCS excels in sealing these applications:

Alumina Refining

Bauxite Grinding Pumps, Caustic Cleaning Preparation, Digester Feed, Desilicator Discharge Pump, Seed Filtrate Pump, Coarse Seed Filter Feed Pumps, Seed Charge

Gold Mining

Carbon In Leach Tails, Concentrate Transfer, Cyanide Transfer, Conditioning Tank feed, Decant Water, Saline Water, Tails Thickener feed

Hard Rock Mining

Dewatering and pumping stations

Coal Prep/Washing

Thickener Underflow, Thickener Overflow

Flue Gas Desulfurization (FGD)

Limestone Recirculation/Scrubber Feed, Ash Pumps, Calcium Sulfate Slurry, Gypsum Slurry, Filtrate Return

Ore Mining

Limes Pump, Concentrator Feed, Tailings/Tailings Booster pumps, Mineral sand slurry, Mineral sand concentrate

Synthetic Rutile Plant

Slurry Transfer Pumps, Acidic Slurry Transfer Pumps

Pigment Plant

Finished Slurry pump, Neutralization feed pump, Chlorine Compressors (GARO)

Industrial Processes

Sugar beets, cement fiber board, diatomaceous earth

Aggregates

Fines recovery, thickener/clarifier underflow, belt-press feed

4 Slurry Seal Configuration Options

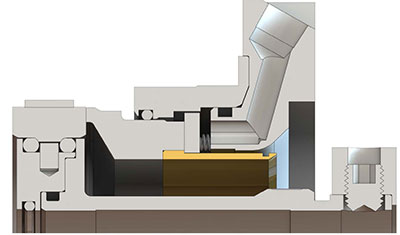

RKCS Version A

Integral Spring Shield is manufactured from a flexible and durable material to effectively shield the springs from debris and slurry during operation. Compatible with API 682 Plan 32. Flush connection optional.

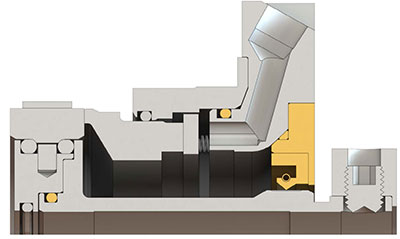

RKCS Version B

(For grease-filled operation)

Addition of bolt-on lip seal assembly and two (2) additional O-rings. Compatible with API 682 Plan 32. Flush connection optional.

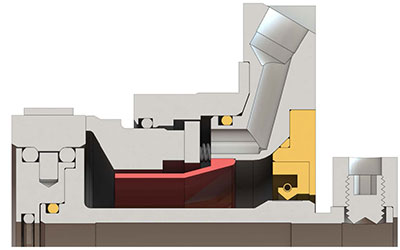

RKCS Version C

(Quench operation)

Fluid Guide Sleeve added to Version B to support the effective removal of debris during quench operation. Compatible with API 682 Plan 32. Flush connection optional.

RKCD (Dual Seal)

A dual seal option designed for the most rigorous slurry processes. In addition to Version C’s Fluid Guide Sleeve, this option is engineered for optimum service when paired with either an API 682 Plan 53A buffer or API 682 Plan 54 barrier fluid seal support system.