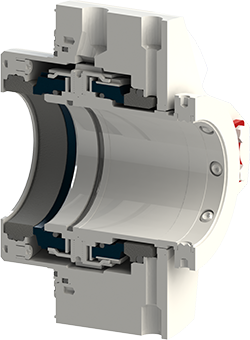

Mechanical Seal Style 90A

API Heavy Duty Rotating Multi-Spring Dual Cartridge Seal

For API 682 Applications

The Flexaseal Style 90A is designed specifically to conform to API 682 Category 2 Applications for Midstream and Downstream Oil and Gas Applications where a Pressurized Dual Arrangement is Desired.

Features

- Oversized Monolithic Seal Faces for superior heat dissipation and durability

- Tang Drive System for reliable face torque transfer and reduced O-Ring hang up

- Heavy Duty Springs to mitigate process debris clogging and reduce spring quantity

- Cushion Mounted Primary Seat to increase reliability in harsh services

- Retained Seal Faces for pressurized barrier systems

- Optimized Pumping Ring for higher barrier fluid flow and better seal cooling

- OD Pressure Design for enhanced solids handling, barrier fluid distribution and seal reliability

Flush Plans 11/53A/53B/54

Specifications

MATERIALS OF CONSTRUCTION

| Rotary Faces: | Silicon Carbide |

| Stationary Faces: | Carbon, Silicon Carbide, Tungsten Carbide |

| Springs: | Hastelloy C276* |

| Metal Parts: | 316 Stainless Steel |

| O. Rings: | Viton®, Ethylene Propylene, AFLAS, Perfluoroelastomer |

Operating Parameters

| Max Temp: | -40 to 400°F / -40 to 204°C |

| Max Pressure: | 600 PSIG / 41.4 bar |

| Max Speed: | 4,500 FPM / 23m/s |

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time. Contact Flexaseal Engineered Seals and Systems, LLC if in doubt.

Downloads

For more information on the style 90A

Quote Request

Depending on your specific needs and application, Flexaseal can help you identify the ideal products. Contact us to tell us about your needs and request a quote.