Features

Product Line Features

- Simple cartridge seal installation.

- Sleeve is isolated from process fluid.

- 3/8″ NPT flush connection allows for cooling and venting of seal.

- 1/4″ NPT vent and drain connections provide differential sizing to minimize the potential of improper piping.

- Non-sparking throttle bushing is positively retained to avoid pressure blow out, minimizing leakage in the event of seal failure.

- Vantage seal glands include flush, vent, and drain connections and a close-clearance, non-sparking throttle bushing to direct any leakage to the drain connection.

- Flush, vent, and drain connections available to be piped at multiple locations.

- Angled gland connections allow for easier pipe fitting.

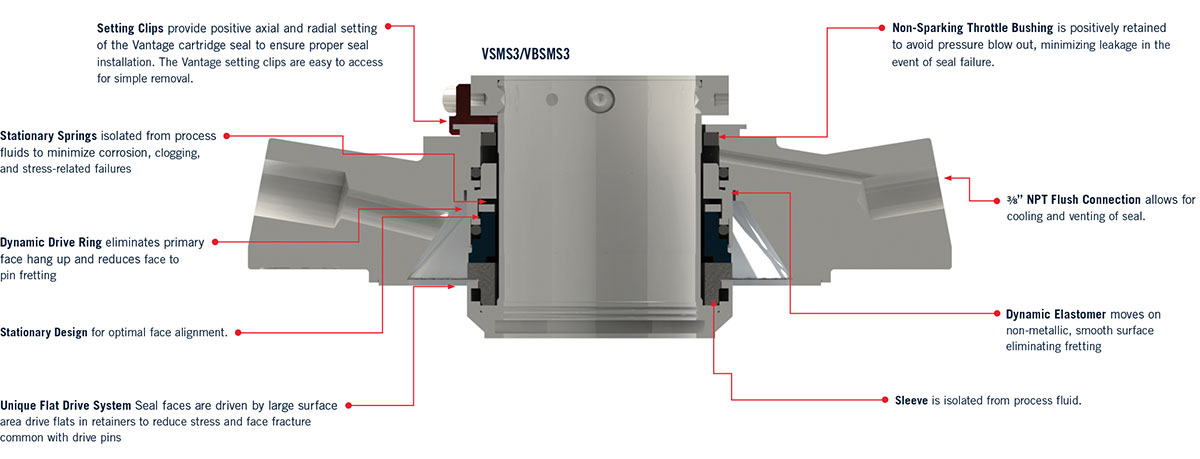

- Setting clips provide positive axial and radial setting of the Vantage cartridge seal to ensure proper seal installation. The Vantage setting clips are easy to access for simple removal.

- Convertible gland design to accept over four (4) design configurations.

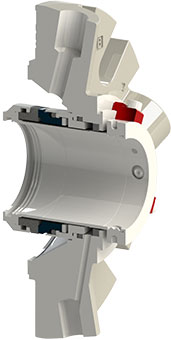

VSMS3/VBSMS3 Features

- Stationary springs isolated from process fluids to minimize corrosion, clogging

- Flat Drive System eliminates face drive pins enhancing face stability and reducing face fractures

- Dynamic Drive Ring eliminates primary face hang up and reduces face to pin fretting

- Dynamic elastomer moves on non-metallic, smooth surface eliminating fretting

- Stationary design for optimal face alignment

- Available in ANSI Big/Taper and Standard Bore

Specifications

Materials of Construction

| Rotating Seal Face: | Sintered Silicon Carbide |

| Stationary Seal face: | Carbon, Sintered Silicon Carbide |

| Springs: | Hastelloy® C276 |

| Metallurgy: | 316 SS |

| Elastomers: | Viton®, Ethylene Propylene, Aflas®, Buna, Neoprene, Perfluorelastomer |

| Gland Gasket: | Glass-filled Teflon™ |

| Throttle Bushing: | Glass-filled Teflon™ |

Operating Parameters

| Temperature: | 400°F (200°C) |

| Pressure: | 300 PSI (20 Bar) |

| Speed: | 4500 FPM |

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time. Contact Flexaseal Engineered Seals and Systems, LLC if in doubt.

Downloads

For more information on the ANSI VSMS3/VBSMS3

Quote Request

Depending on your specific needs and application, Flexaseal can help you identify the ideal products. Contact us to tell us about your needs and request a quote.