Case Study: Mining

Aggregate Production Quarry Solves Seal Leaking Challenge

Equipment: Heavy-Duty High Head Slurry Pumps in Series

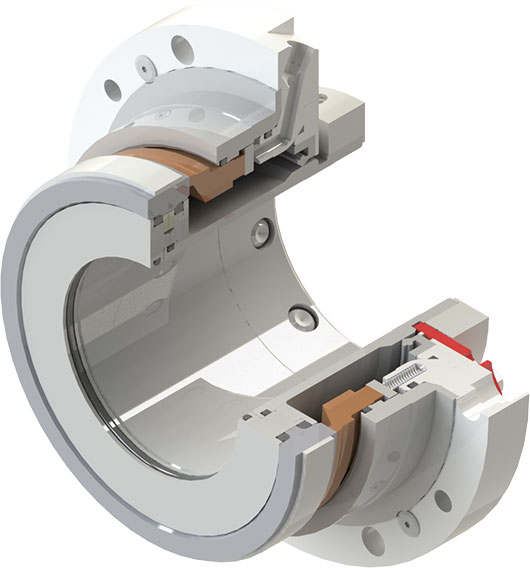

Mechanical Seal: 100mm Style RKCS, flushless, grease-quenched, slurry seal

Temperature: Ambient

Pressure: 1st Stage: 80 psi (5.5 bar) 2nd Stage: 160 psi (11 bar)

Speed: 1300 rpm

Product: Thickener Underflow, 55% w/w, 80 μm average partical size

Introduction

The client is a leading producer of construction aggregates, including crushed stone, sand, and gravel. The client’s aggregates production operation in the Mideast processes their fine waste material using a high-rate thickener to dewater the tailings from their process stream. The thickener underflow averages 55% solids by weight slurry and is evacuated with two heavy-duty slurry pumps in series operating at elevated pressures.

Solution: RKCS Slurry Seal

Flexaseal’s RKCS product line was identified as the ideal solution for these applications. The heavy-duty flushless mechanical seal for slurry pumping applications was designed to handle the most challenging slurry environments without requiring seal water or packing. The 100mm seals were installed in the slurry pumps by the pump manufacturer at their factory.

The RKCS series mechanical seal features a robust design that can withstand the most challenging slurry environments. The seal faces are made fromsilicon carbide and graphite-loaded silicon carbide, which provide excellent wear resistance and heat dissipation. The seal also features a grease quench apparatus that delivers grease at atmospheric pressure over time to capture and expel any fluid that may egress across the seal faces.

Results: Zero External Leakage

Upon startup, the RKCS series mechanical seals performed as expected with zero external leakage, and continued to operate admirably with zero maintenance interventions over a significant period of time. Had these pumps been packed, over this time the equipment would typically need to be repacked several times, and the general area around the slurry pumps would remain wet and covered in viscous and slippery fine sludge, which is a housekeeping and safety concern.

Of note, during the startup and system optimization phase, the pumps were cavitating due to suction issues from overly thickened slurry being pumped, but the seals continued to perform nominally with zero external leakage.

The elimination of seal water reduces the risk of spills and leaks, which can cause costly rotating assembly failures and safety hazards. The improved reliability of the mechanical seal has also reduced the risk of unplanned downtime, which can impact production and revenue.

Exceeding Expectations

The client is extremely happy with the results and plans to implement this seal design into every major thickener underflow application they have moving forward. By eliminating the need for seal water, the client has reduced maintenance interventions, downtime, and safety hazards while significantly reducing overall cost implications over time.

Conclusion: A Successful Transformation

The success of the RKCS series mechanical seal in the client’s slurry pumping operations highlights the importance of selecting the right sealing solution for challenging applications. The robust design of the RKCS series mechanical seal provides reliable sealing without the need for seal water or packing. The elimination of seal water reduces maintenance interventions, downtime, and safety hazards, while improving the safety and reliability of slurry pumping operations. The RKCS series mechanical seal is an excellent example of how innovative sealing solutions can help companies reduce costs, improve safety, and enhance productivity.