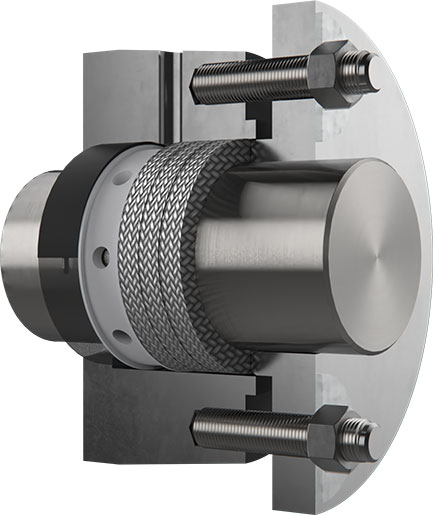

ViseSeal

Stabilizing Shafts, Conserving Water

ViseSeal solves two critical issues in rotating equipment sealed with packing: shaft instability and high water consumption. The innovative thermoplastic split-bearing design paired with our high-performance packing provide robust shaft support, reducing vibrations and enhancing equipment performance. Additionally, the ViseSeal system significantly reduces water usage, making your operations more efficient and sustainable.

ViseSeal

Design Features & Benefits

- Why the ViseSeal?

- Downloads

- Quote Request

Why the ViseSeal?

ViseSeal stands out for its superior shaft stabilization and unmatched water conservation.

It not only enhances your equipment’s performance by reducing vibrations but also makes your operations more environmentally friendly and cost-effective by significantly reducing water usage. Plus, with its easy field repacking feature, ViseSeal ensures longer Mean Time Between Failures (MTBF) and less downtime.

Choose ViseSeal for a stable, sustainable, and efficient sealing solution.

Downloads

Quote Request

The ViseSeal excels in sealing these applications:

Pulp & Paper

Raw Water, Cooling Water, Chemical Handling, Thick Stock (High Consistency), Medium Consistency Stock, Green Liquor, White Liquor, Black Liquor, Waste Water Treatment, Power House

Alumina Refining

Bauxite Grinding Pumps, Caustic Cleaning Preparation, Digester Feed, Desilicator Discharge Pump, Seed Filtrate Pump, Coarse Seed Filter Feed Pumps, Seed Charge

Gold Mining

Carbon In Leach Tails, Concentrate Transfer, Cyanide Transfer, Conditioning Tank feed, Decant Water, Saline Water, Tails Thickener feed

Hard Rock Mining

Dewatering and pumping stations

Flue Gas Desulfurization (FGD)

Limestone Recirculation/Scrubber Feed, Ash Pumps, Calcium Sulfate Slurry, Gypsum Slurry, Filtrate Return

Ore Mining

Limes Pump, Concentrator Feed, Tailings/Tailings Booster pumps, Mineral sand slurry, Mineral sand concentrate

Synthetic Rutile Plant

Slurry Transfer Pumps, Acidic Slurry Transfer Pumps

Pigment Plant

Finished Slurry pump, Neutralization feed pump, Chlorine Compressors (GARO)

Industrial Processes

Sugar beets, cement fiber board, diatomaceous earth

Aggregates

Fines recovery, thickener/clarifier underflow, belt-press feed

Coal Prep/Washing

Thickener Underflow, Thickener Overflow

4 Configuration Options

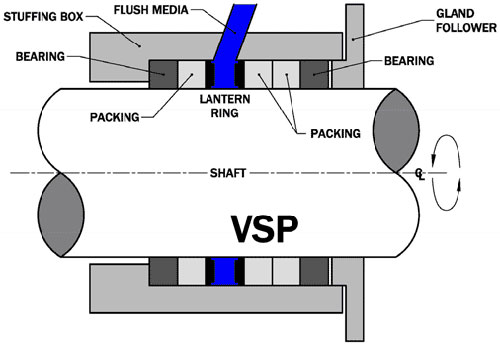

ViseSeal For Pumps (VSP)

Features:

- Two split/pinned ViseSeal bearings separated by packing and a removable lantern ring.

- Die-formed rings of high-performance packings are compressed between the ViseSeal bearings.

Benefits:

The ViseSeal kits provide the following: reduced water consumption, shaft support, vibration dampening, shaft centering, eliminates packing extrusion, easy to maintain by removing the packing and lantern ring in the field for repacking, no pump removal for repack, reduced packing adjustments and longer MTBF.

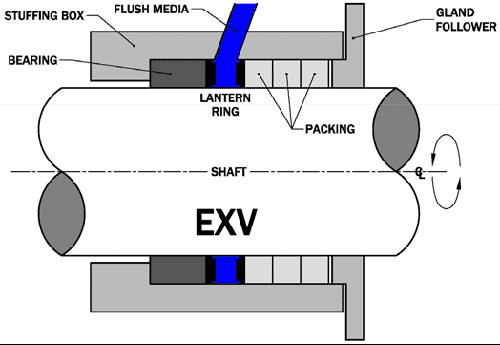

ViseSeal Extended (EXV)

Features:

- A ViseSeal EXV kit contains a close tolerance ViseSeal bearing, a PTFE lantern ring, and high quality.

- Die-formed packing rings.

Benefits:

- Viseseal bearing protects soft packing from destructive shaft movement, vibration, and process interruptions.

- The lantern ring can be removed for easy repacking (no more need to remove equipment to repack pumps).

- Packing rings are free to seal without the need to support the shaft and deal with excessive shaft movement.

- Longer MTBF (Mean Time Between Failure), less sleeve wear, longer packing life, and fewer packing adjustments.

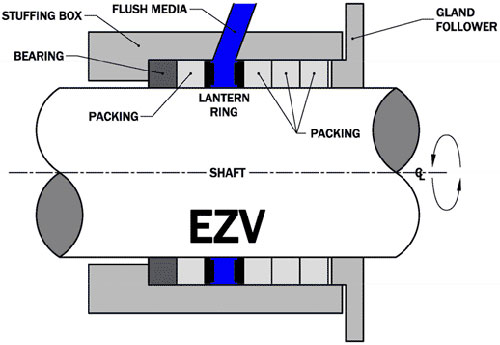

ViseSeal EZ Vise (EZV)

Features:

- A ViseSeal EZVkit contains a close clearance ViseSeal bearing, a ring of die-formed packing between the ViseSeal bearing and a PTFE lantern ring, die-formed packing rings outboard.

Benefits:

- ViseSeal bearing reduces shaft movement, minimizes vibration and closes clearances in stuffing boxes.

- Water consumption is reduced with packing ring on both sides of the lantern ring.

- Packing lasts longer, with fewer adjustments.

- Field repack without the need to remove equipment.

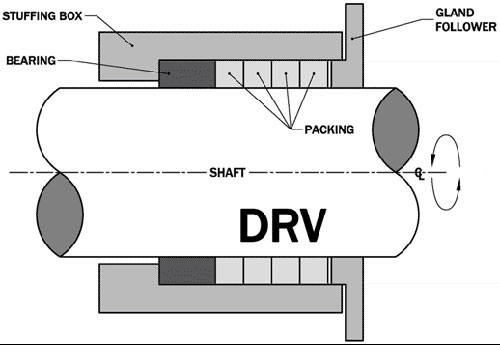

ViseSeal Dry Vise (DRV)

Features:

- One split/pinned ViseSeal bearing from the bottom of the box with rings of high-quality die-formed packing.

Benefits:

- TNo product dilution – shaft stabilization to protect packing.