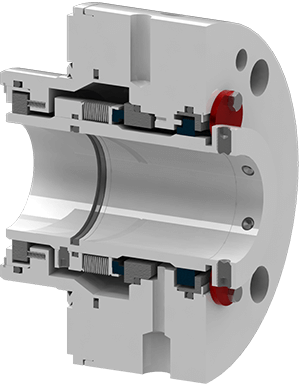

Mechanical Seal Style 53A

API Heavy Duty Rotating Metal Bellows Cartridge Seal

For Medium Temperature and Dirty Critical Services

The Flexaseal Style 53A cartridge seal is specifically designed for ruggedness and durability to withstand higher temperature or dirty services The rotating bellows is self-cleaning for greater reliability in dirty services.

Multiple bellows materials available based on process conditions and fluids. Double-ply bellows designs for higher pressures.

Static elastomers throughout for elimination of O-ring abrasion and energized face hang up.

The Style 53A cartridge seal is uniquely customizable to your specific application requirements. API 682 Compliant options are also available.

Features

API 682 Arrangement 1

Type B Seal

Configuration 1CW-FL

- Heavy duty cartridge design

- Self-cleaning rotating bellows

- Hydraulically balanced

- Multi-point injection arrangement

- Piloted gland to positively center seal assembly

- Flush, quench, drain gland with 1/2″ NPT for process side and 3/8″ NPT for atmospheric side to help eliminate improper piping assembly

- Carbon floating bushing

- Metal-to-metal confined gland gasket

- Double ply bellows designs available for higher pressures

Specifications

Materials of Construction

| Faces: | Antimony Impregnated Carbon, Nickel Bound Tungsten Carbide, Sintered Silicon Carbide, Graphite Loaded Silicon Carbide |

| Welded Bellows: | AM350HT, Inconel 718TM, Hastelloy C-276TM. Single and Double-Ply bellows options available. |

| Gland Bushings: | Bronze, Carbon |

| Lantern Ring: | PTFE |

| Standard Metallurgy: | 316 SS with low-expansion Alloy 42 retainer. Other material options available, please consult Flexaseal. |

Operating Parameters

| Max Temp: | 550°F (288 °C) |

| Max Pressure: | 600 psig (41 bar) |

| Max Speed: | 4500 fpm (23 m/s) |

*Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time. Contact Flexaseal if in doubt.

Downloads

For more information on style 53A

Quote Request

Depending on your specific needs and application, Flexaseal can help you identify the ideal products. Contact us to tell us about your needs and request a quote.