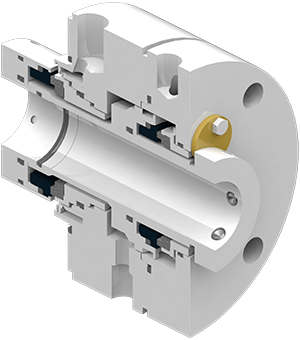

Mechanical Seal Style 79A

API Heavy Duty Stationary Tandem Multi-Spring Double Cartridge Seal

For Critical Services Where Leakage Must be Completely Contained

The Flexaseal Style 79A tandem cartridge seal is specifically designed for ruggedness and durability to withstand services were leakage and emissions must be completely contained. Design elements include retained faces to allow for pressurized or unpressurized barrier systems, stationary design for maximum runout compensation and pilot gland to positively center the seal.

The Style 79A cartridge seal is uniquely customizable to your specific application requirements. API 682 Compliant options are also available.

Features

- Incorporated pumping ring improves the movement – and the cooling effect – of the barrier fluid during operation

- Tandem design maintains product and barrier fluid on O.D. of both seals for increased safety and heat dissipation

- A tangential connection maximizes the flow of barrier fluid

- Can be operated in pressurized or non-pressurized state configurations

- Springs are located out of the product

- Double balanced inboard face allows for reverse pressures in upset conditions

- Easy to install cartridge design

- Metric and ANSI Sizes Available

- Can be easily adapted to satisfy high pressure applications or in cases of extreme run out

- Retained faces eliminate troublesome drive pins

- Hydraulically balanced design

- API 682 Type A Tandem Arrangement 2 and 3 available

Specifications

Operating Parameters

| Max Temp: | 400°F (204°C) |

| Max Pressure: | 1,200 PSI |

| Max Speed: | 4500 FPM (22 m/sec) |

Note: Max Temperature / pressure / speed indicate operating extremes independently and do not imply the seal will function at these extremes at the same time. Contact Flexaseal Engineered Seals and Systems, LLC if in doubt.

Downloads

For more information on the style 79A

Quote Request

Depending on your specific needs and application, Flexaseal can help you identify the ideal products. Contact us to tell us about your needs and request a quote.