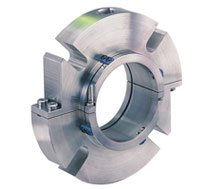

THE WORLDS FIRST SPLIT CARTRIDGE MECHANICAL SEAL REDUCES DOWNTIME FOR CHALLENGING AND TIME-CONSUMING INSTALLATIONS

The Flexaseal Style 85 split cartridge mechanical seal requires just two pieces to be handled for installation. Both sealing faces are safely secured in the cartridge halves and cannot be cocked, chipped or scarred. The Flexaseal 2-piece split cartridge mechanical seal is completely assembled and pressure tested before it is shipped to you.

85

Fully Split Cartridge Mechanical Seal

85M

Fully Split Cartridge Mechanical Seal for Mixers and Agitators

Quick Contact

For general inquiries, sales or quotes.